Goal and Direction

Remote / Automated Drilling Operation

The drilling process for oil and gas and geothermal energy is characterized by fragmented operations with many parties involved and many interfaces and high uncertainty, especially with respect to underground conditions. This uncertainty will cause and enforce high costs in different aspects of the drilling operation and will impact the CO2 emissions to the environment.

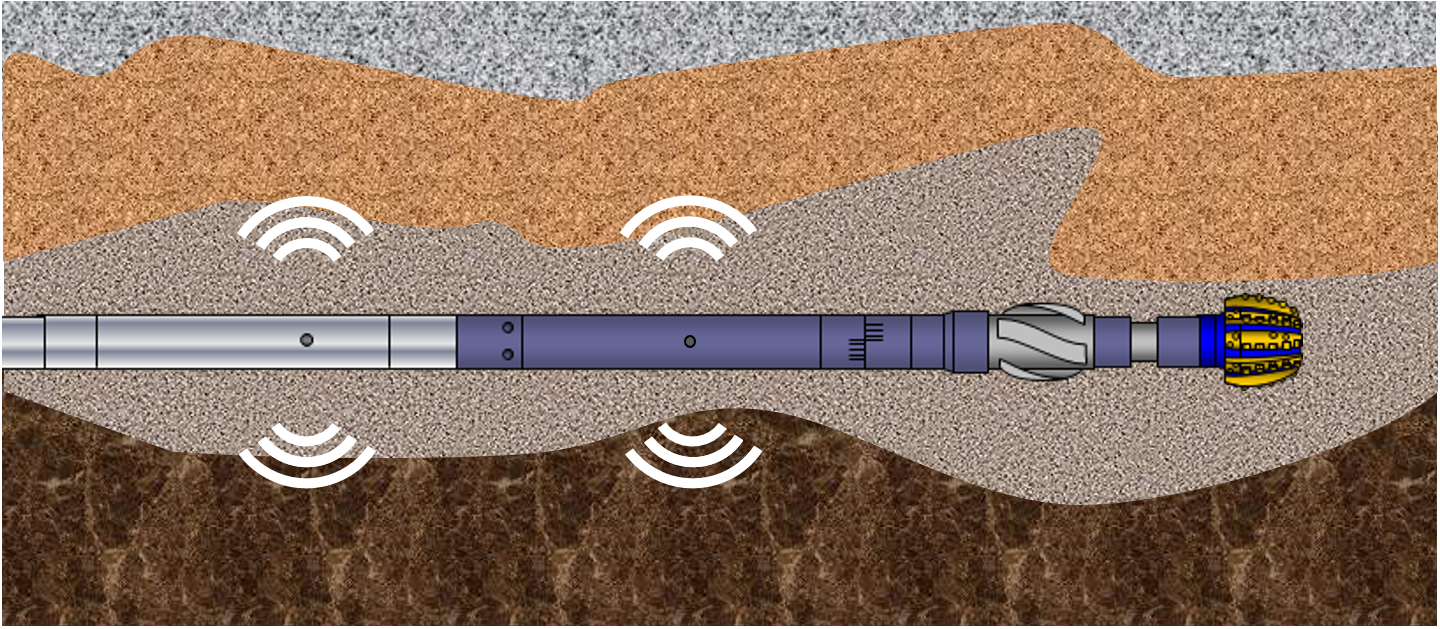

Automated drilling and autonomous drilling operation will be the key to reducing the operation cost and carbon footprint in the environment. Digitization tools are crucial, digitalization can be implemented both in the planning and operational phase. Digitalization of the planning phase will reflect in the preparation of the drilling program based on input data from offset wells. The automated and autonomous drilling operations will be based on both surface and downhole sensor data. Using downhole tools to record real-time data while drilling (like along string measurement (ASM) devices along the wired drill pipe) and combining it with surface recorded data will lead us to optimize the operation in real time with data-driven decision support.

Predicting the next step in the operational sequence, monitoring both surface and downhole data (which would be difficult for the driller to monitor the huge amount of data), detecting and mitigating both surface and downhole issues (like kick and loss detection, cutting concentration monitoring and etc.) automatically in real-time is the aim and the goal to perform remote drilling operations and automated drilling processes.