DigiWellData Services

DigiWellData company focuses on developing applications to optimize Drilling and Completion operations and Well integrity for the purpose of remote and automated operation.

DigiWellData drilling and completion team provides engineering services to Exploration and Production clients. Engineering services include:

Well planning

Well design

Well Integrity

MPD design

Real-time drilling optimization (based on both surface and downhole recorded data)

Downhole Mud Loss Indicator

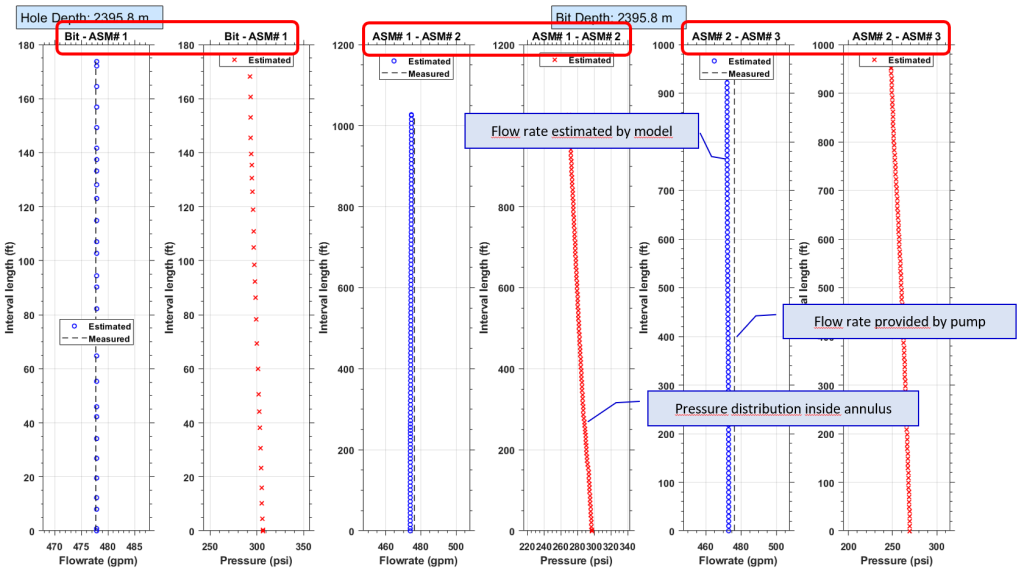

An authentic real-time approach for monitoring and control of downhole fluid hydraulics should incorporate both model

physics and downhole measurements. Physical models are

formulated as differential equations of mass and momentum conservation, which are discretized along the borehole utilizing the finite element method. Using this approach in conjunction with high-frequency ASM data, flow rate and pressure along the borehole domain can be predicted in real time.

Flowrate and Pressure change between Bit-ASM1, ASM1-ASM2, and also between ASM2-ASM3

Recorded Mud loss detection

Lithology Change Indicator

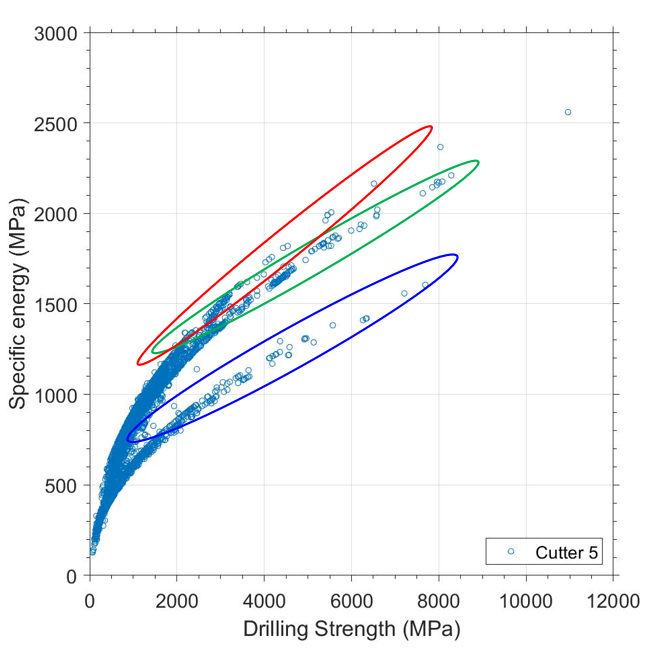

The other approach of this software is to detect lithology changes by using specific energy in real-time. Based on this methodology, the wear condition of all cutters can be predicted and estimated accurately. The relationship between drilling strength and specific energy can also be used to identify differences in rock drill ability.

Specific Energy vs Strength

Recorded Lithology change detection

Automated Dull Grading

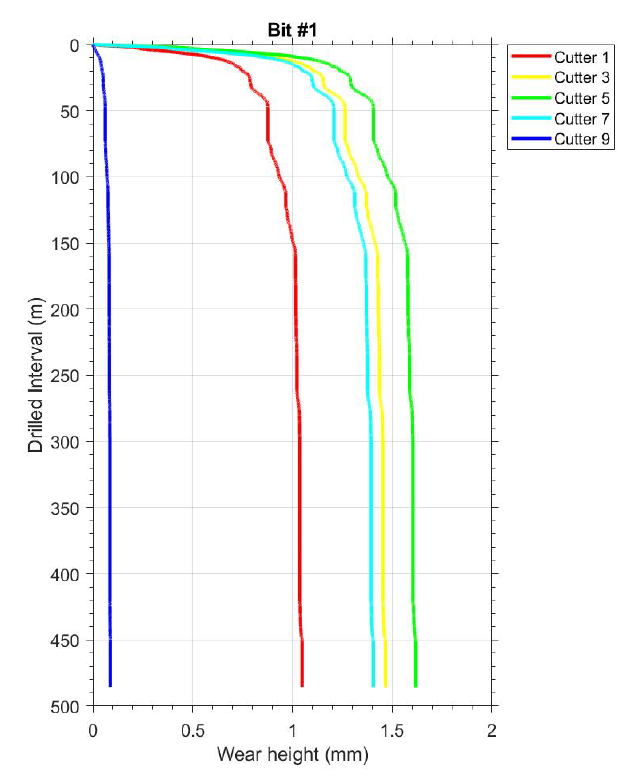

Most well records or some of the post-assessment techniques can be used to select bits based on nearby well records or other criteria. An innovative data-analytic approach is being developed to monitor the PDC bit conditions in real time. This approach incorporates and analyzes bit design parameters as well as drilling data collected along the wired pipe using a string measurement system. With this technique, it is possible to estimate and monitor bit status in real-time or in other words real-time automated dull grading.

Cutter Wear Height vs Drill Depth